Controlled roughness

Besides cleaning, sandblasting treatments also create in the treated steel surface an artificial profile (which is a rough surface), that observed through a microscope, presents an irregular series of unevenly distributes bumps and incisions (peaks and valleys). The profile, also improperly called "roughness", improves the adhesion of paint to the surface. For this reason, the artificial modification obtained with surface sandblasting is also known as “anchor pattern". For some coating types, the anchor pattern might need to be kept within certain ranges: for medium/low thickness coatings the anchor pattern must be lower, while for those which are very thick we recommend deeper and more marked incisions in order to increase adhesion. Hence the need to have a controlled roughness treatment that gives and maintains the desired results. It is therefore useful to know that the depth of the incisions depends on the grit size (granulometry), but is also influenced by the speed and the physical characteristics of the abrasive material (shape, hardness and specific weight).

With grit size and blasting speed being equal, angular metallic grit makes for deeper incisions, even on burrs; followed by corundum (aluminum oxide), silicon carbide, slag and finally silica sand and laurite. The "shot" granules makes for a smoother profile, known as "peening" with less deep valleys. The terms "shot" and "grit" are used to describe the shape of the granules: round and angular, respectively. Granules of the “grit” type is suitable for deburring treatments, due to their angular shape. Surfaces can be treated to create a specific “texture”, known as “orange” peel. This texture is often used in the treatment of moulds.

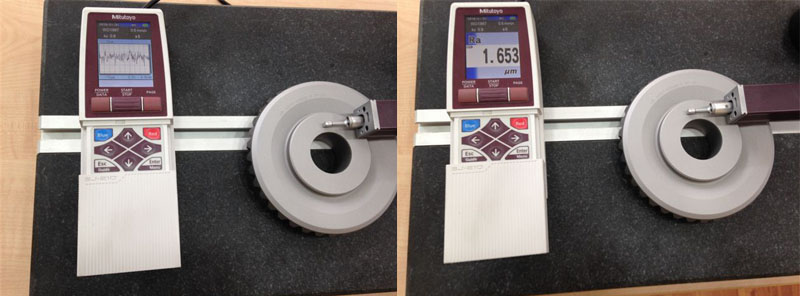

• Read the roughness Tester (left) and values (right).