Shot-peening

Shot-peening differs from sandblasting for the purpose intended as more similar to rolling because it operates more on the plasticity of the material that the abrasion.

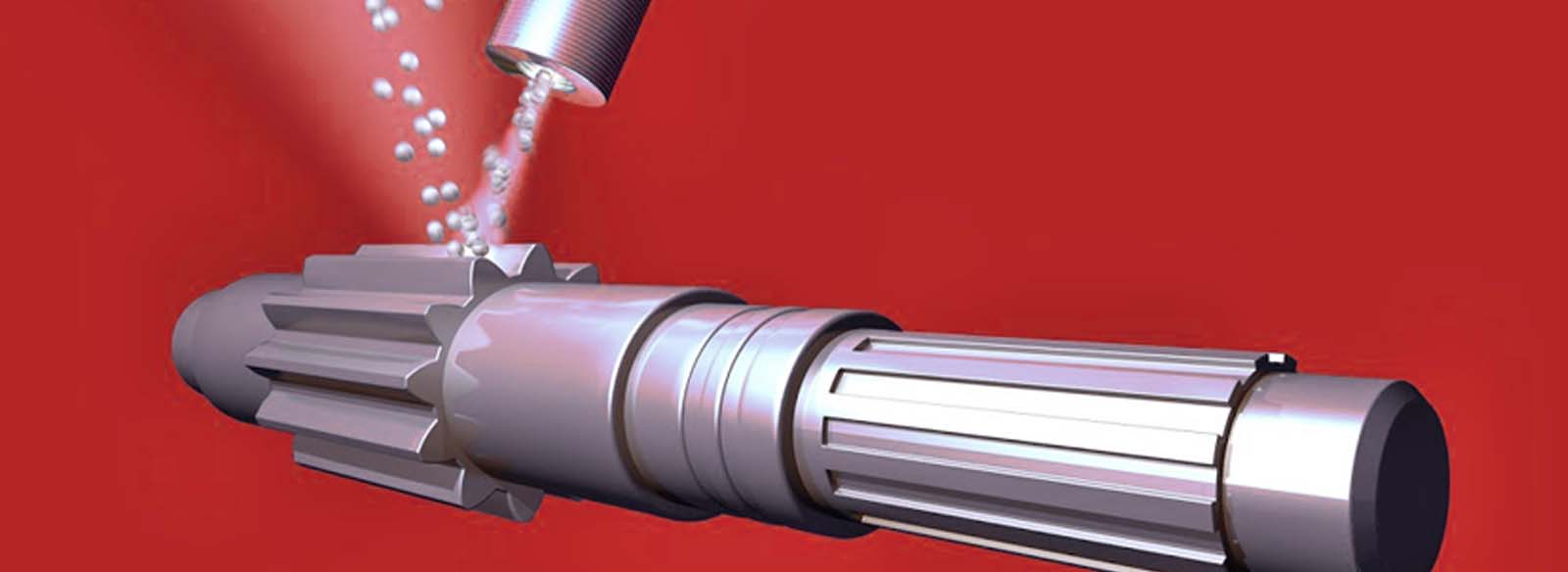

Shot-peening is a cold working process in which small spherical media called shots, or rods obtained cutting a wire (called cut-wire) bombard the surface of a part.

During the shot-peening process, each piece of shot that strikes the material acts as a tiny peening hammer, imparting a small dimple to the surface.

Metallic parts such as springs or rods, but also exceptionally pieces in bronze, brass, titanium, aluminum and various alloys may be submitted to this process.

Shot-peening plays a major role in the AEROSPACE and AUTOMOTIVE fields, since almost all fatigue failures or stress corrosion originates on the part surface.

Shot-peening provides a considerable increase in the mechanical part life. In fact, the maximum compressive residual stress produced just below the surface of a part by shot-peening is at least as great as one-half the yield strength of the material being shot-peened.

Controlled shot-peening is also used to create the aerodynamic curvatures of metallic plates of airplane wings. Additional applications for shot-peening include closing porosity, improving resistance to intergranular corrosion, straightening of distorted parts, surface finishing, testing the bond strength of coatings and work hardening through cold work to improve wear characteristics.

Shot-peening compressive stresses help increase resistance to fatigue failures, even in aggressive environments or corrosion fatigue, stress corrosion cracking, hydrogen assisted cracking, galling or erosion caused by cavitation.