PCT improves your products

Over the last few years, surface treatments and finishing have turned from optional to standard processes, having obtained a key role in part manufacturing in certain markets.

The main reasons behind this trend are: technological development and product differentiation.

Technological development, (think of the significant development of coatings such as PVD, CVD, APS, and VPS, chemical nickel, hard chrome, metal-rubber adhesions) has emphasized the importance of surface treatments in the usage requirements and resistance of materials and coatings. Nowadays, product differentiation has become an essential strategy for companies wishing to stay competitive. So that surface treatments such as sandblasting and shot-peening have become an indispensable way of finishing products.

Sandblasting and shot-peening are very often two kinds of processes in which the technological level and the abilities of technicians are not adequately considered and interpreted.

Their real potential and range of applications are still widely unknown.

Few indeed know the broad areas of intervention and the really surprising results in terms of quality and flexibility that can be reached. Over the last few years, large businesses, having more money to invest, have been already discovering the potential of sandblasting and shot-peening treatments and have been applying them to treat their products. For the sake of clarity, we will say that they are both extremely versatile surface treatments having different purposes and both require the use of inert materials. In shot-peening they have a spherical shape, while in sandblasting the abrasive materials are irregularly shaped and angular.

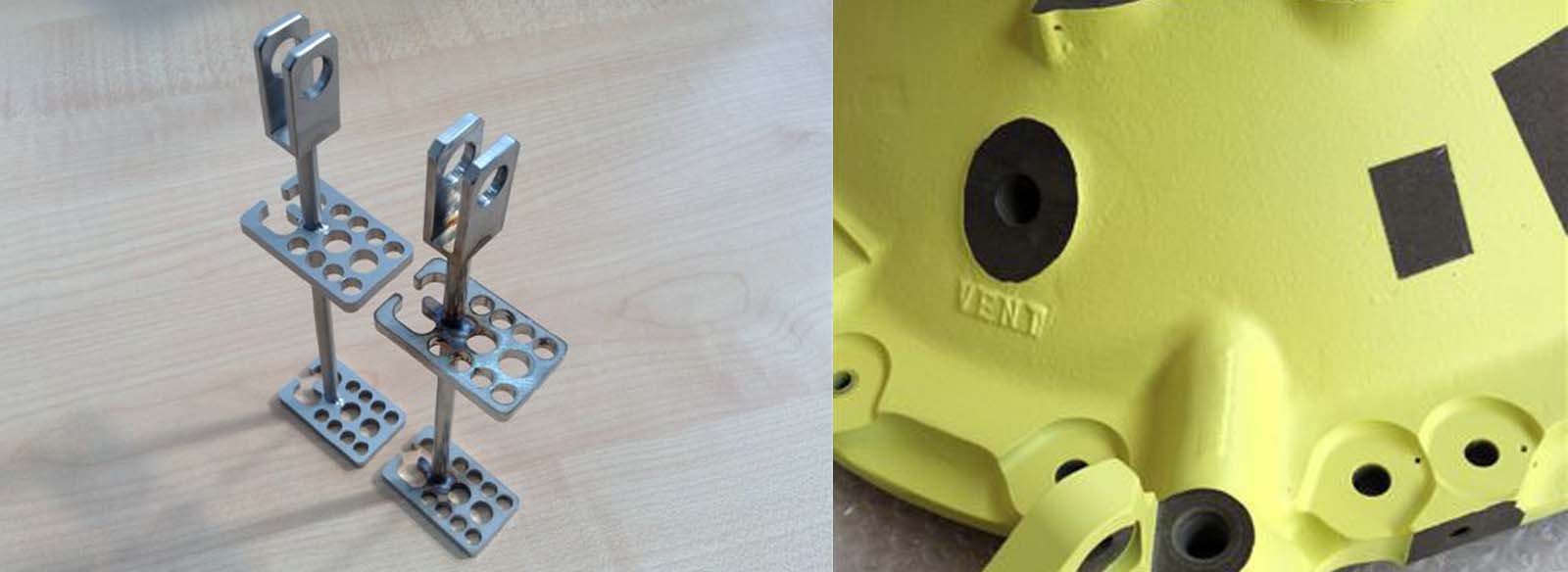

SOME APPLICATIONS

Lets explain some applications as possible processes and applications that see PCT as an ideal partner for your business.

First of all quality

The adequacy of shot-peening and sandblasting processes must be constantly monitored and guaranteed by quality in order to avoid compromising the geometrical and micro-geometrical features of the parts.

The presence of technically sound equipment is not a guarantee of success, which can only be reached through a good knowledge of the process and any related issues as the certifications that we have acquired, along with the skills of our professionals.

For example using the right parameters such as the working pressure, the inert adequate to the dimensions and to the purpose of processing as to obtain the desired result quality.

All this together with a thorough knowledge of the potential of these processes provide feasibility opportunities for small to large businesses.

In the sandblasting/shot-peening fields, any possible problem such as excessive material removal, undesired rounding of the edges and out-of-specification roughness, can be solved by PTC, thanks to a careful analysis of customers’ working requirements and processes problems.

The operator manual ability and speed are not enough to achieve the best results! Our experience in PTC allows us to carry out processes in a correct and appropriate manner in order to achieve the best results and give added value to the customers’ business that choose PCT as partner in terms of maintenance costs and economies of scale.

PCT a proficiency guarantee For the sake of convenience, we have grouped the possible applications into 6 categories:

1. Cleaning and material removal

2. Surface finishing

3. Deburring

4. Anchorage

5. Controlled roughness

6. Controlled material removal